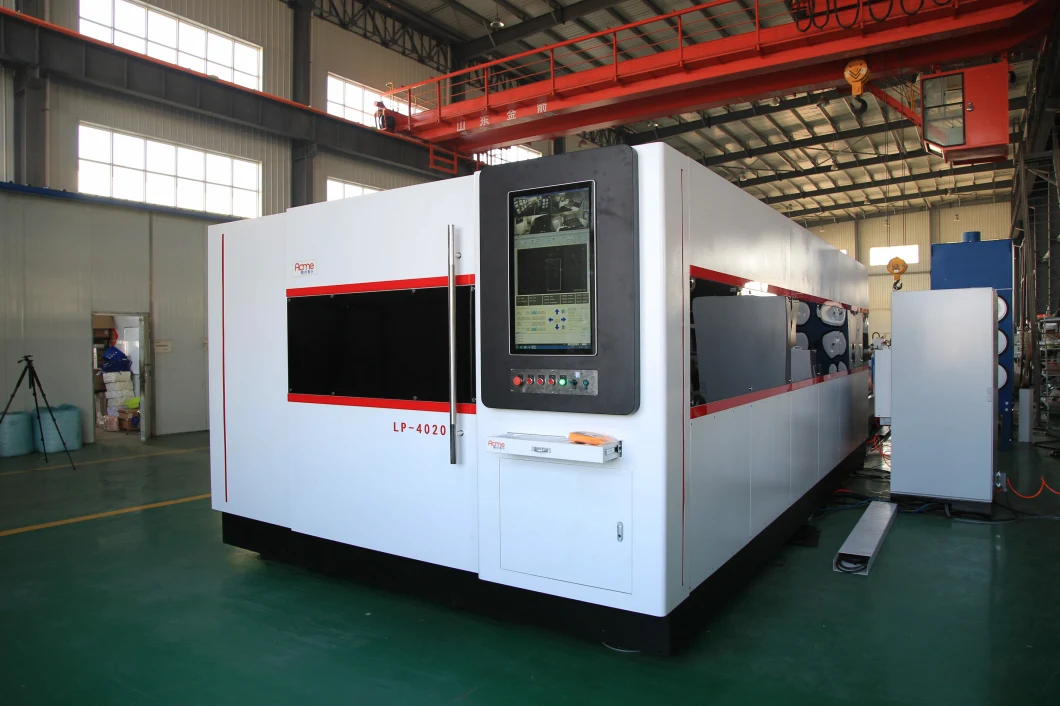

Fiber Laser Cutting Systems

Description

Basic Info

| Model NO. | LP-4020D |

| Laser Technology | Fiber Laser |

| Power | 2000W-12000W |

| Laser Source | Ipg/Raycus |

| Motor | Yaskawa |

| Rail and Rack | Hiwin/Yyc |

| Control System | Cypcut |

| Water Cooling | Hanli/Tongfei |

| Size | 1500*3000mm/2000*4000mm |

| Aftersales | 2-Year Warranty |

| G.W. | 15t |

| Transport Package | FCL/LCL |

| Specification | 10500*3478*2340mm |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 720 Sets/Year |

Product Description

Fiber Laser Cutting Systems

Features

LP-4020D fiber laser cutting machine with high power is specially used to cut thick sheet, such as stainless steel, carbon steel, mild steel, galvanized steel, aluminum, brass, copper and various other metal materials.

1. Welded aluminum gantry, light but hardness reach to T6

2. 8.5T net weight machine bed with high temperature annealing, whole steel sheet welded bed with high accuracy

3. Germany Precitec Auto-focusing Laser Head

4. Chain for Table Exchanging is pretected and supported in the tunnel,making the exchange process stable.

Samples

Cutting Capability of IPG

| RESONATOR IPG | YLS-1KW | YLS-2KW | YLS-3KW | YLS-4KW | YLS-6KW |

| Power (W) | 1000 | 2000 | 3000 | 4000 | 6000 |

| Recommended cooling power (kW) | 2,1 | 4,2 | 6,4 | 8,5 | 12,6 |

| Electrical supply (kW) | 3,1 | 6,1 | 9,1 | 12,1 | 18,2 |

| Maximum sheet thickness: | |||||

| Steel (mm) | 10 | 15 | 20 | 20 | 25 |

| Stainless Steel (mm) | 4 | 8 | 12 | 15 | 20 |

| Aluminium (mm) | 2 | 6 | 12 | 12 | 15 |

| Brass (mm) | 2 | 4 | 6 | 8 | 10 |

| Copper (mm) | 2 | 4 | 6 | 8 | 10 |

Factory

Shipment in Flat RackWhy Choose Fiber Laser for Stainless Steel, Mild Steel and Aluminum, etc., ?

More companies than ever before are investing in fiber lasers. While the automotive industry was undoubtedly the early adopter, this relatively new solution is being snapped up across the board and when you consider the advantages, it's easy to see why.

EXTRA SPEED

The sheer speed of fiber laser markers makes them the first choice for customers looking to increase efficiency. They're the fastest laser marking technology at their wavelength, delivering marking times of less than one second for some applications. While older, more established laser technology is available-including diode-pumped solid-state (DPSS) lasers, lamp-pumped lasers, and carbon dioxide (CO2) lasers-none can beat a fiber laser for combined mark speed and quality.

This means fiber lasers can break new ground. For example, one of Laser Lines' customers is an automotive component manufacturer that needs to mark serial codes exceptionally fast-in under half a second-which wouldn't be possible with any other type of laser.

ENERGY EFFECIENCY

Despite being faster, fiber lasers are energy-efficient compared to the alternatives. Not only does this result in reduced power consumption, but it also helps make the system simpler, smaller, and more reliable.

Fiber laser technology uses basic air cooling rather than an additional chiller unit, which would be costly and cumbersome. With many businesses finding both cash and floor space in short supply, compact and efficient fiber laser marking solutions are proving to be the right fit.

LONG LIFE

The life expectancy of a fiber laser far exceeds that of other laser solutions. In fact, the diode module in a fiber laser typically last three times longer than other technologies. Most lasers have a life of around 30,000 hours, which typically equates to about 15 years' use.

Fiber lasers have an expected life of around 100,000 hours, which means about 45 years' use. Saying that, will companies still be using the same fiber laser in 45 years? I doubt it! Regardless, this option does deliver an impressive return on investment.

Prev: 1000W Professional Fiber Laser Welding System with CE Certificate From Baokun Machinery Company

Next: 1/4"~10" Clear/Transparent PVC Plastic Spiral Steel Wire Suction/Discharge Water Soft Hose

Our Contact

[email protected]

[email protected]